By Michael Johnson

In the latest phase of my project, I have been experimenting with 3D printing Dead Sea Scroll fragments to see how they might be useful for reconstructing manuscripts. My work has focused mostly on the Thanksgiving Hymns and the War Scroll from Cave 1 (1QHa and 1QM), though the question also applies to manuscript reconstruction in general.

The question driving this experiment is whether 3D printing manuscripts (so far I have only printed fragments) offers enough gains for research to be worth the effort or whether it is just a gimmick that offers little of serious value. Although I have only just begun to 3D print portions of manuscripts, I can answer this question with a preliminary affirmative.

Before weighing the advantages of 3D printing, I should say more about what I mean by “3D printing Dead Sea Scrolls.” I think many people unfamiliar with the process would hear that phrase and conjure up images of a printer cranking out columns of plasticized manuscript that precisely replicate it down to the unevenness of its surface, its texture, and perhaps even its pliability. In an ideal world and with great effort it might be possible to do something along these lines, but with manuscripts like the Dead Sea Scrolls it is not feasible. Since reconstructions should be built primarily on the images closest to the manuscript’s time of discovery, the starting point is not a three-dimensional manuscript but two-dimensional photos that were taken shortly after the manuscript’s unrolling. There is not sufficient data about depth in these photos, so characteristics like thickness, texture, and unevenness of the surface are lost to us. In theory we could capture this data from the manuscripts themselves by 3D scanning them, but much of the material is obscured by measures taken to conserve them, such as backing parts of columns and fragments with Japanese paper, enclosing them in Stabilitex (polyester netting), or mounting them between glass plates. Since the discovery of the Scrolls, the material has had 70 years to shrink and warp as the collagen has degraded and the skin has gelatinized, so there is no guarantee that accurate data would be recovered if it were possible to scan them.

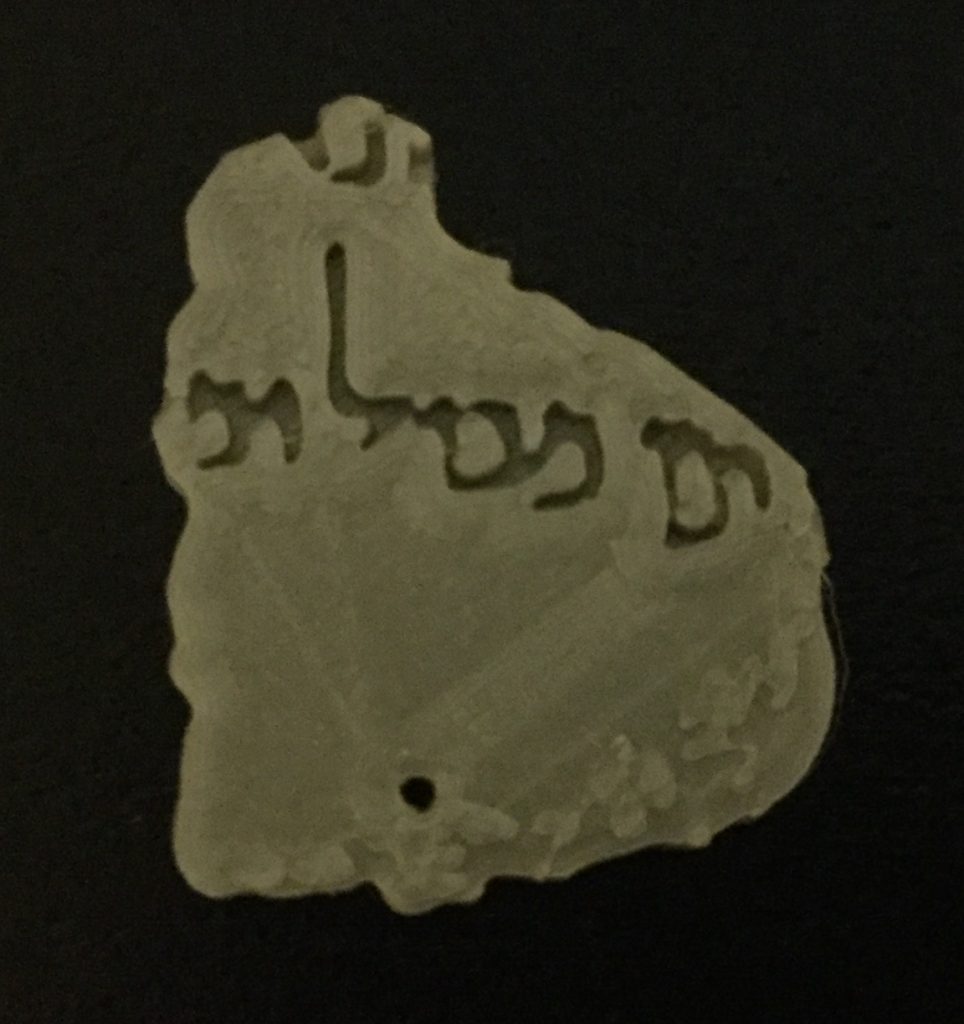

My process and objectives are much simpler than printing an perfect facsimile. Manuscript reconstruction is primarily about accurately arranging fragments in their original positions in the manuscript. The most important features for this process are the shapes and edges of the fragments, any notable surface characteristics (peculiarities or patterns of the skin or papyrus), surface damages (mold, delamination, insect damage), writing (textual and paratextual), and any margins, seams or seam impressions where they have survived. In my initial printings, I have only sought to create scale printed models with accurate edges and which have just enough thickness to represent what I consider to be the distinctive features in relief. For example, in my printing of 1QM frg. 3, I inset the area of the where ink is visible on the fragment and raised the areas where significant mold is present.

This is fairly easy to do and results in a scaled model that isolates and emphasizes what a scholar considers to be diagnostically significant for the reconstruction. To date, I have only printed single fragments, but the process can be scaled up for entire columns, sheets, and manuscripts.

Benefits for Manuscript Reconstruction

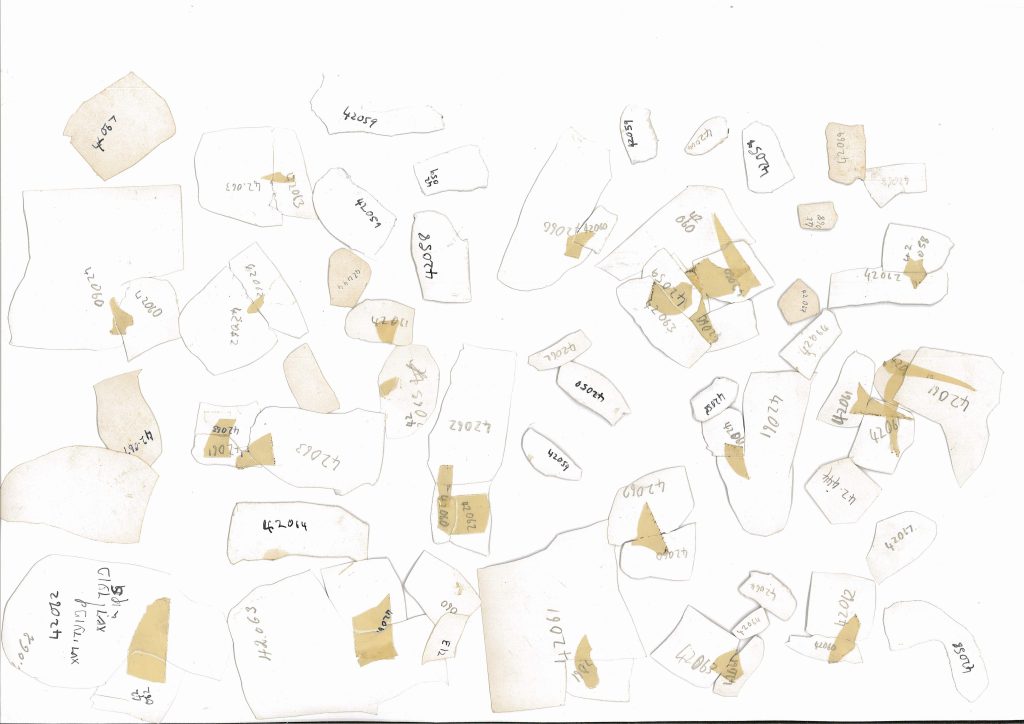

The benefits of 3D printing reconstructions can be divided into two phases of the process: experimentation and dissemination. The first phase of manuscript reconstruction involves experimenting with arrangements of fragments by exploring the possibility of material joins of one fragment edge to another or the placing of fragments near one another in light of repeating patterns of damage that run through the entire scroll. This process involves a lot of trial and error. In the past, Scrolls scholars have taken photographic plates of the fragments and cut them out with scissors.

Various hypotheses could be locked in by taping the fragments onto a sheet of paper and photocopying them. This process has been updated with the advent of image editing software like Photoshop or GIMP, which removes the arduous process of cutting out fragments by hand. Although platforms like Photoshop are sufficient for the basic task, they lack the tactile element of physically arranging material at scale. In Photoshop, one often has to zoom in to place fragments precisely, and it is easy to loose a sense of proportion when continuously working under magnification. There are also complications with version management and file size that can get out of control in the process of exploring the options with high quality images. 3D printed models of fragments are essentially fabricated elements of a Photoshop reconstruction that allow a scholar to quickly rough out reconstructions in analog before composing something more precisely in Photoshop. These preliminary arrangements of fragments can be quickly documented with a photo and filed away. Once the possibilities are narrowed down to the best candidates, they can be reproduced more exactingly as high definition composite images in Photoshop. This process gives a tactile familiarity with the fragments and a concrete sense of scale that is otherwise lost in purely digital process.

One might not be convinced of the value of 3D printed fragments for experimentation because everyone works differently—a tool that one person finds indispensable another might find superfluous—but the benefits for disseminating research are difficult to ignore. In Dead Sea Scrolls scholarship, one of the chief difficulties in disseminating the results of manuscript reconstructions has been their inability to persuade because they seem rather subjective. This is due in part to insufficient documentation of the arguments underlying manuscript reconstructions. The arguments deal with shapes and patterns, which are difficult to express clearly in the primary medium of the discipline: textual description. There are, however, ways to show one’s work using digital tools to create visualizations that document stages of the reconstructive argument that are otherwise difficult to express concisely in words, including but not limited to 3D printing.

3D printed models of fragments or complexes of related fragments can be used in presentations to give the audience a tactile experience of the reconstructive argument. The same benefits of the 3D printed models for the researcher in the experimentation phase also accrue to the specialist when evaluating the reconstruction. A better sense of scale and a first-hand examination of the reconstruction—perhaps even with the chance to experiment with their own alternatives—enables the audience to become a more active participant in the discussion. By isolating what the researcher considers to be diagnostically significant, the printed models also make the premises of reconstructive arguments more prominent. These benefits equip audiences in presentations to better interpret what the researcher sees in the images and to offer quality feedback on projects with an otherwise steep learning curve.

There are also applications of 3D printing for publications. The stereolithography (STL) files that are the basis for 3D printer instructions are very small and would not be burdensome to maintain as an online supplement for a journal article or book. STL files of configurations of key fragment clusters in a reconstruction would be useful not only for the reader evaluate the argument in the publication, but also as a starting point for their own alternative proposal. In this way, the models of the fragments can have an afterlife beyond the initial project if the project data is published.

Conclusion

My initial foray into 3D printing has yielded a handy tool for experimenting with manuscript reconstructions and for visualizing results for other researchers. As I have been 3D modelling my reconstructions for other visualizations in my Sherman Centre project, it has been a reflexive impulse to want to print them, just as we expect to be able to print documents to edit, evaluate, and disseminate them. I find that when I am writing, I do my best editing when I am working with a hard copy, and the same applies to manuscript reconstructions. I find there is a value to working physically with 3D printed surrogates for the manuscript rather than digitally mediating the process of reconstruction through a computer interface at every stage of research. So far, I have only scratched the surface of the uses of printed models of scroll fragments, but I have found that it is worth the effort. Consequently, when I am asked why I 3D print fragments, I will have to respond with my own question—why not? If 3D printing provides greater familiarity with the fragments and their reconstruction, not only for myself but also for audiences and future researchers, then it would be a shame not to.

Leave a Reply